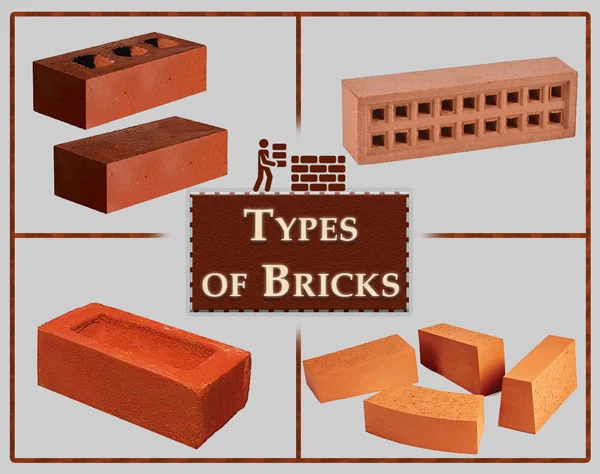

Bricks

Bricks come in various types and sizes with different constituent materials. From conventional burnt clay bricks to modern concrete blocks, each type of brick has distinct properties and varied applications. Therefore, when building a new structure, exploring the types of bricks is essential to make informed decisions. Keep reading on to know more about the types of bricks available.

What Are Bricks?

Bricks are one of the primary building materials. They are made from clay, shale, or other materials such as concrete or fly ash. Bricks come in diverse types and are manufactured by employing varied processes. Their manufacturing process depends on the material used to ensure durability and strength. The primary purpose of bricks is to create sturdy walls, pavements, and other structural elements like buildings, and bridges.

Advantages of Red Bricks

- They are much durable and hard that they can withstand severe wind and extreme weather conditions.

- Red bricks are great insulators, they store heat energy absorbed during daytime and release heat after the sun set. This helps in keeping the house warm in winter and cool in summer.

- Red bricks create a very little amount of waste and produce less environmental pollution, hence they are eco-friendly and degrade completely.

- The compressive strength of a red brick is good enough for any ordinary construction.

- The raw material is easily available and the cost of maintenance is also low for red bricks

- Red bricks are highly fire resistant and easily reusable and recyclable.

- They have a better sound performance where it is capable of blocking the sound from outside.

Advantages of Fly ash bricks

- Fly ash bricks absorb less heat and considering the Indian climate, it makes it better when compared to clay bricks.

- From the cost front, it requires less mortar during construction. Further, the machine that we provide requires less labor too. Our machines are made keeping in mind the costs associated with water wastage and raw material wastage too. You hence save in the breakage front (15%), the plaster and jointing front (15%) and curing and labor front (7%). So Q Green fly ash brick machines reduce the overall costs.

- The compressive strength is very high and they are less porous. They absorb less waterand saves cost there, as well.

- It is environmentally friendly and hence allows your business to take a step towards sustainable development. Q-Green machines are green machines too, that promote environmental protection and conservation. Production of fly ash bricks requires no fossil fuel and hence does not lead to the emission of green house gases.

- Production of clay bricksdamages the top-soil and this is prevented in the manufacturing process of fly ash bricks. There is no pollution or environmental damage, as a result of which it has been put into the white category of products.

- Fly ash bricks are stronger, more uniform and denser as compared to clay bricks. While their mortar consumptionis low, their wastage is only about 1% as against that of clay bricks which are about 10%.

ADVANTAGES OF Concrete bricks

- Fly ash bricks absorb less heat and considering the Indian climate, it makes it better when compared to clay bricks.

- From the cost front, it requires less mortar during construction. Further, the machine that we provide requires less labor too. Our machines are made keeping in mind the costs associated with water wastage and raw material wastage too. You hence save in the breakage front (15%), the plaster and jointing front (15%) and curing and labor front (7%). So Q Green fly ash brick machines reduce the overall costs.

- The compressive strength is very high and they are less porous. They absorb less waterand saves cost there, as well.

- It is environmentally friendly and hence allows your business to take a step towards sustainable development. Q-Green machines are green machines too, that promote environmental protection and conservation. Production of fly ash bricks requires no fossil fuel and hence does not lead to the emission of green house gases.

- Production of clay bricksdamages the top-soil and this is prevented in the manufacturing process of fly ash bricks. There is no pollution or environmental damage, as a result of which it has been put into the white category of products.

- Fly ash bricks are stronger, more uniform and denser as compared to clay bricks. While their mortar consumptionis low, their wastage is only about 1% as against that of clay bricks which are about 10%.

ADVANTAGES OF FIREBRICK

- High Insulating Value –The light weight firebricks make possible thinner furnace walls, improved efficiency and lower operating costs.

- Strength –The high compressive strength of firebricks allows for self-supporting structures at elevated temperatures. Firebricks are compatible with dense fire brick, and add strength to the whole construction.

- Low Heat Storage – Lower heat storage versus dense brick means reduced fuel costs and faster heat-ups in cyclically operated heating equipment.

- High Purity – Firebricks are low in impurities such as iron, which can adversely affect refractory performance in many applications. They are used in many furnaces with controlled atmospheres.

- Accurate Dimensions– Fire Brick are machined to precise dimensions, courses can be laid quickly and easily, and the result is a stronger, tighter refractory lining resulting in less heat loss through the joints.

Clients Testimonials

Amazing Feedback Say About Services

Happy Client

Happy Client

Happy Client

Happy Client

Get in Touch

Request for Callback

Strengthening Our Journey, Together

Our Supporting Partners