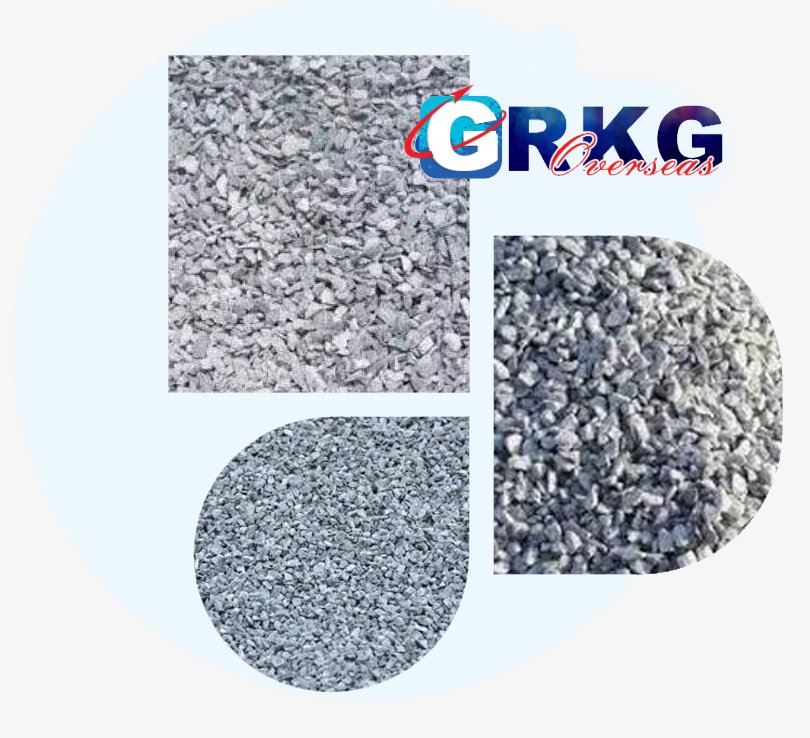

Crushed Stone

Crushed stone aggregates are produced by crushing quarried rock, then screening it to sizes appropriate for the intended use. Production of crushed stone has three stages: Primary crushing to break down the stone to a manageable size; secondary and tertiary crushing to render the rocks into sizes specific to their applications; and screening to separate the crushed stone for further processing or for finished products sizes. HSN Code: 25171010.

Production Process

Extraction

Large rocks are extracted from quarries or mines.

Crushing

Extracted rocks are fed into crushers, where they are broken down into smaller, manageable sizes.

Screening

The crushed rocks are sorted into various sizes using screens and classifiers.

Washing

To remove impurities and ensure the aggregates are clean, they may be washed.

Stockpiling

The final products are stockpiled and ready for distribution.

Fine

Fine crushed stone aggregates consist of particle sizes that are typically less than 3/8-inch (9 mm). Fine aggregates are used in asphalt, concrete, backfill, construction and specialty applications.

Common uses for fine crused stone

• Concrete

• Asphalt

• Backfill and bedding materials

• Skid resistance on ice or snow

• Agricultural-lime (Ag-lime)

• Stabilized earth or reinforced soils

Sizes and Designations

ASTM, AASHTO & DOT products available.

Common designations include, but are not limited to: Concrete Sand, Asphalt Sand, Manufactured Sand (Man Sand), Dry & Washed Screenings

Coarse

Coarse aggregates consist of gravel, crushed stone or recycled concrete with particle sizes of ranging from 3/8-inch to 1.5 inches. Coarse aggregates are used in a wide range of construction applications, notably in concrete and asphalt mixes.

Common uses for coarse crushed stone

• Concrete aggregate

• Asphalt aggregate

• Drainage stone

• Seal coat chips for roadways

• Stone roads and driveways

• Road base

• Backfill

Sizes and Designations

ASTM, AASHTO & DOT products available.

Common designations include, but are not limited to: #4, #467, #5, #56, #57, #6, #67, #7, #8, #89, #9

Base Coarse

Dense-graded base course refers to crushed stone aggregates with a range of particle sizes, usually 1-1/2-inch and smaller, that produce a dense layer of stone with a minimum amount of voids.

Common uses for base coarse crushed stone

• Foundation for asphalt pavement

• Foundation for concrete pads and pavements

• Unpaved roads and shoulders

• Backfill for pipe and underground utilities

• Cement-treated base

Sizes and Designations

Sizes and designations vary by location due to governing agency requirements.

Common designations include, but are not limited to: Base, Subbase, Dense Graded Base, -Crushed Stone Base, Graded Aggregate Base (GAB), Aggregate Base Coarse(ABC), Macadam Base Coarse (MBC)

Ballast

Large coarse aggregates that consist of crushed stone (hardstone such as rhyolite, granite and sometimes dolomite) with particle sizes ranging from 1 ½ inches to 4 inches. Typical uses include construction applications and railroad ballast.

Common uses for ballast crushed stone

• Railroad ballast

• Construction entrances

• Rough site pads

Sizes and Designations

ASTM, AASHTO & AREMA products available.

Common designations include, but are not limited to: #1, #2, #3, #4, #5

Clients Testimonials

Amazing Feedback Say About Services

Happy Client

Happy Client

Happy Client

Happy Client

Get in Touch

Request for Callback

Strengthening Our Journey, Together

Our Supporting Partners